lundi 16 mars 2015

Inscription à :

Publier les commentaires (Atom)

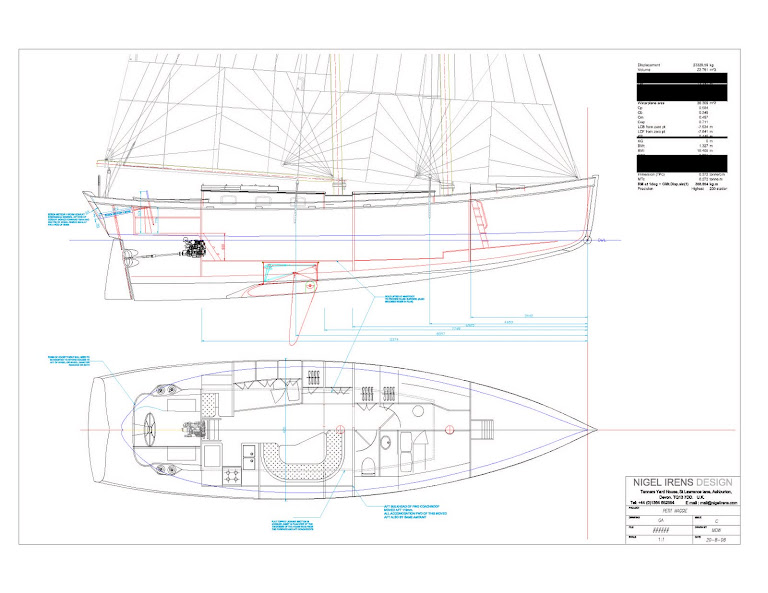

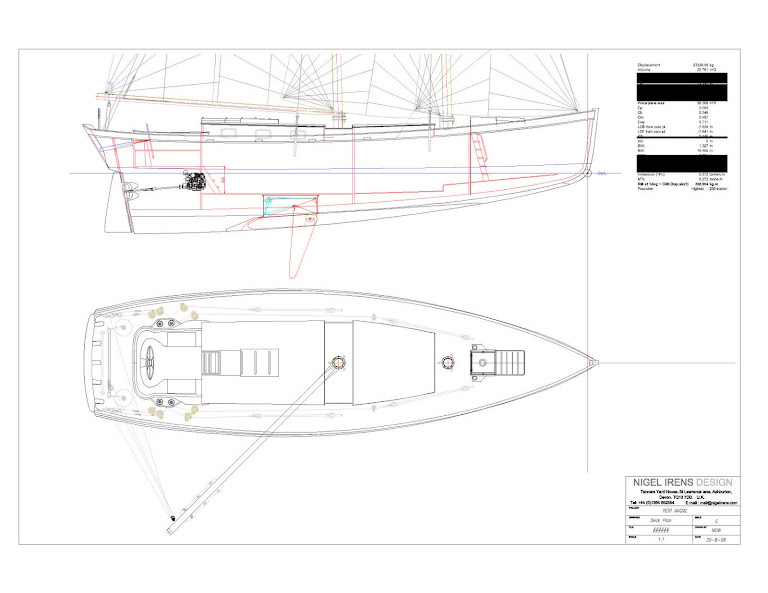

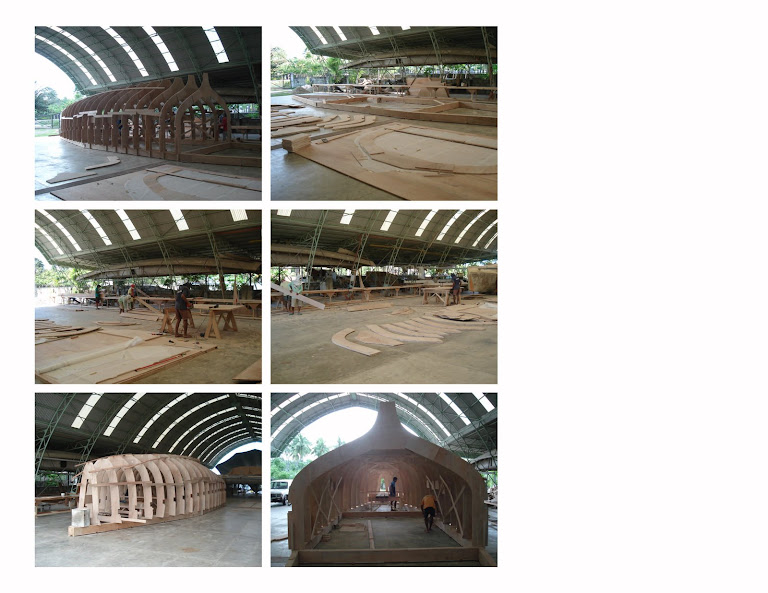

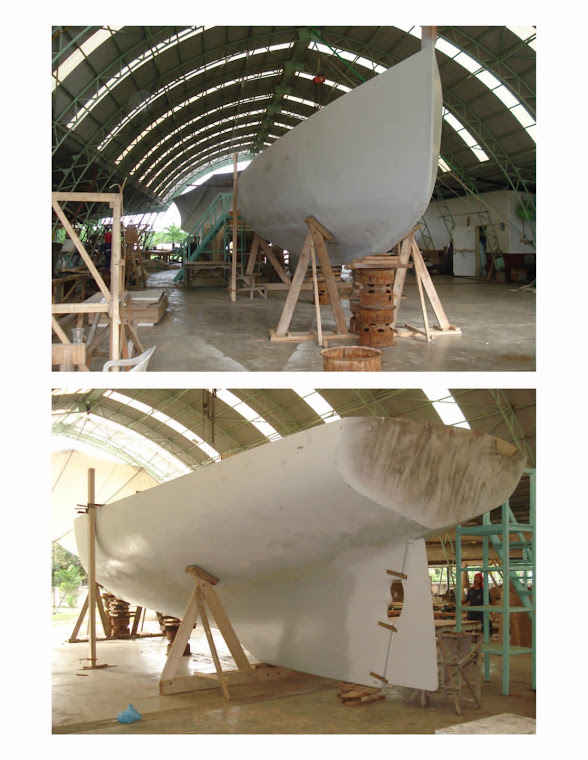

50 foot cruising schooner construction in philippines

Fusion Schooner 50’

Actual march 2015

Design : Nigel Irens

Cruising sailing boat

Hull type : long keel/centerboard

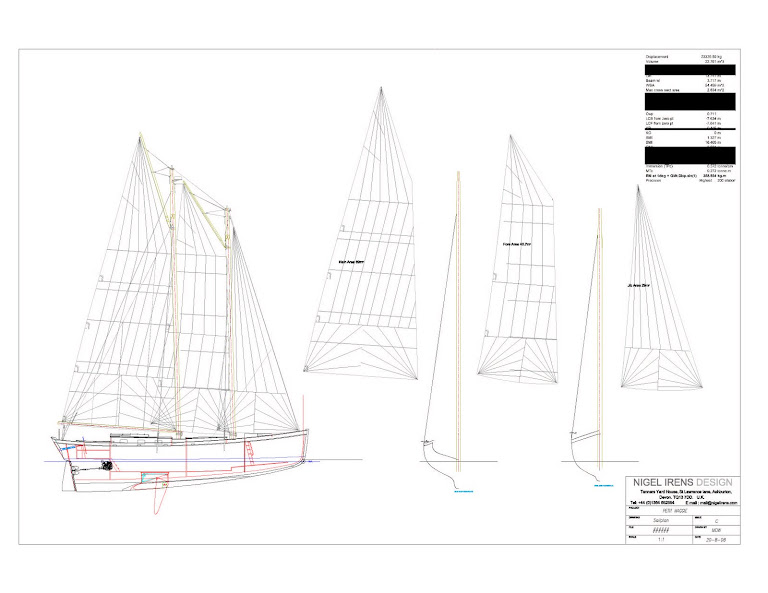

Rigging type : schooner gaff rig

LOA : 14.97 meter

Beam : 4.2 meter

Draft : 1.68 meter ( 3.2meter centerboard down)

Displ. : 21 metric ton

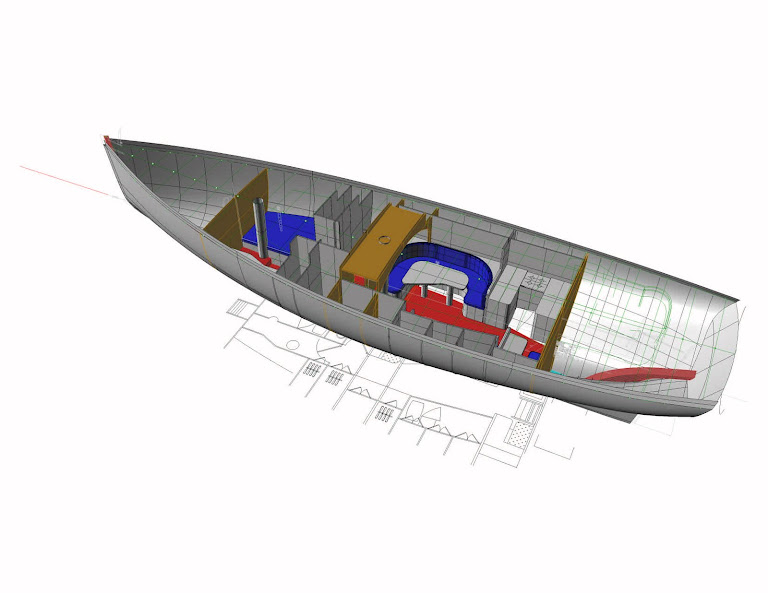

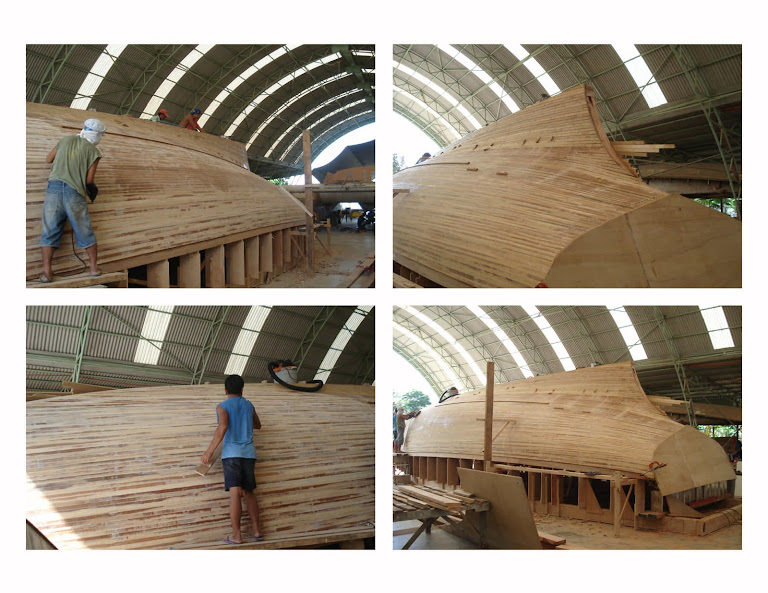

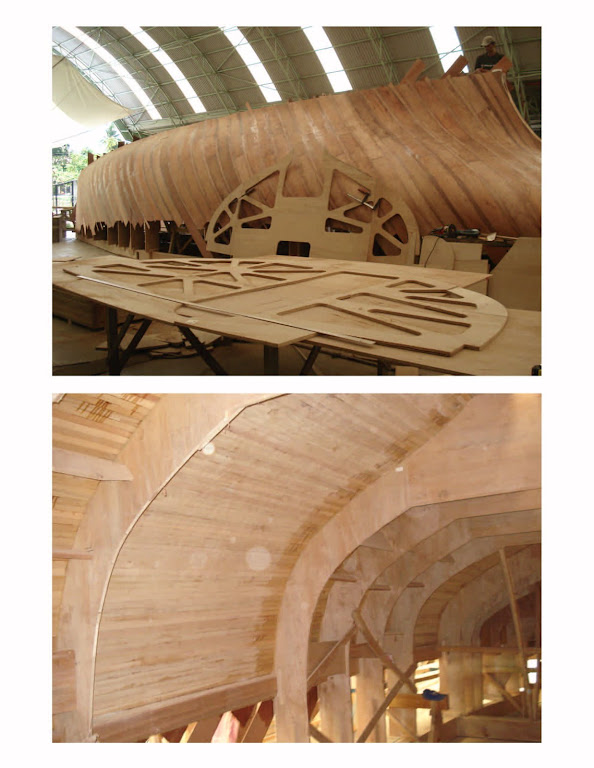

Hull Construction:

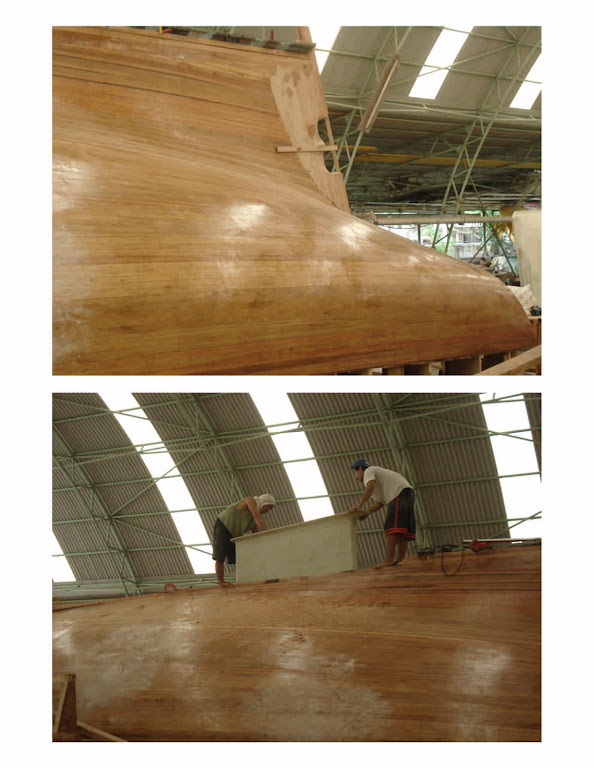

As per Lloyd’s regulation hull will be 40mm thickness, in strip-planking/cold molded epoxy, with yellow meranti for the strip and two layer in diagonal of Philippine mahogany wood (red dark Luan) kiln dry, all the hull is completely encapsulated with bi-directional fiberglass, we use local epoxy type PRC#7 who was formulated by the U.S. Navy many years ago when they still had bases in the Philippines.

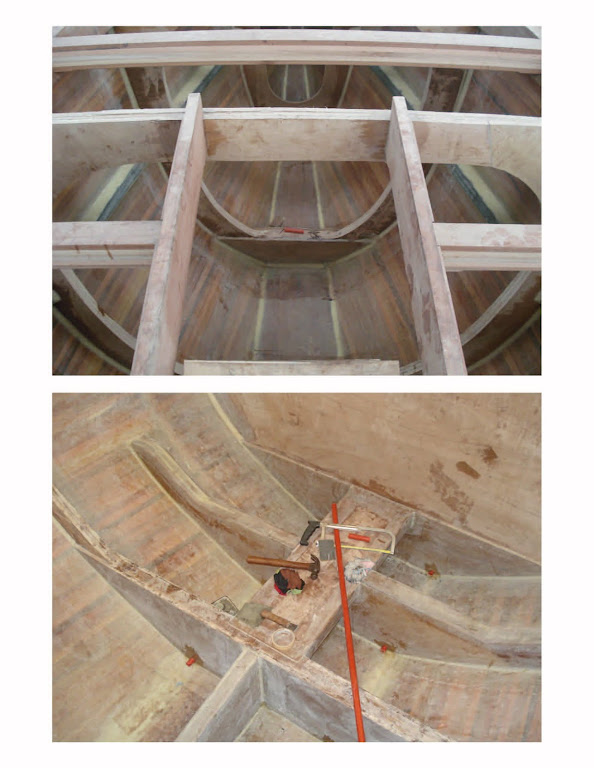

Bulkhead are marine sandwich Plywood/red Luan , all plywood are BS1088 standard, floor frame in massive red dark Luan, with epoxy lamination

Hull have a epoxy faring and final painting with polyurethane paint on Dupont hard built epoxy primer.

Ballast:

8100 kg of lead/antimony, fastening with Nickel Aluminium Bronze (NAB) bolt 20mm

nuts are SS316 .

Centerboard:

Laminated wood in monolytic epoxy box, hydraulic lifting system.

Steering system:

Wooden wheel with SS chain and SS cable on bronze sector.

Emergency helm in galvanized steel

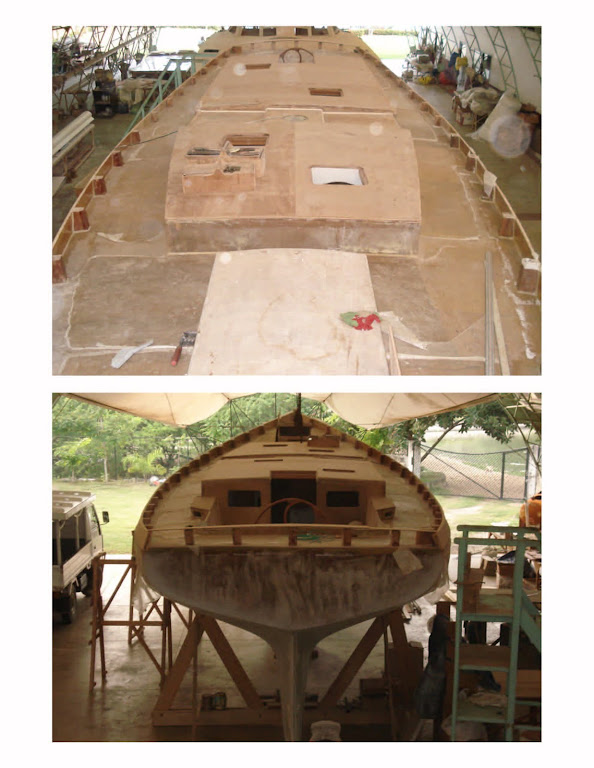

Deck :

Marine plywood with epoxy lamination , non slip polyurethane paint

All beam in laminated red dark luan.

Roof in marine plywood BS 1088 with external lamination and polyurethane painting

Hatch : 6 portholes, tempered glass 8mm , 4 opening hatch on the roof SS 316, Mandeck

Propulsion:

New 2015 Kubota V3300, 3.3 liter, 65 HP rating @ 2600 rpm , 4 cylinders diesel naturally aspired,

New 2015 gearbox Twin disck TMC 260 ratio 1.56 :1

Flexible mounting, wet exhaust, PSS gland

SS304 shaft, bronze tube

feathering prop type propeller darglow , SS blades

Accommodation:

All in Philippine mahogany, door with woven Rotan canvas sealed with epoxy varnish

All internal looker painted white color with polyurethane paint

Toilette

Separate bathroom with shower, sink and head

Head electric

Kitchen

4 Burner + oven, gas

Fridge& Freezer compartment top opening.

12 volt compressor danfoss new 2015

Diesel Fuel tank

2 Vinyl Esther laminated tank total 650 liters

Daily tank 120 liters

Raccord type filter/water separator.

Fresh Water Tank.

2 Vinyl Esther laminated tanks total 650 liters

Pressure pump with HDP piping to bathroom/kitchen/deck shower.

Electrical

1 X 12 volts, 70 amp emergency starting batteries for the engine

2 X 12 volt 120 amp starter batteries for engine & anchoring winch

6 X 6 volts 200 amps deep cycle batteries for service 12volts 600amp

all wire marine type

electric panel with fuse breaker

all light LED type

alternator on main engine 45amp for starting batteries

alternator on main engine 130 amp for service and anchoring winch batteries charging

with sterling high power regulator, 3 stage charger

automatic 3 stage batteries charger 60 amp for the 3 bank

sinus converter 12/220volt 50htz 1000 watt

watermaker

Genset

5 kw Kubota marine diesel with 160 amp 12volt + external regulator

Electronic

GPS Seiwa

Deep sounder / fishfinder Seiwa on plotter screen

Deep sounder Nasa clipper

Wind indicator Nasa Clipper

Chart plotter Explorer 3 Seiwa

LCD/LED 12v screen 19 inch for plotter

Autopilot AP3 seiwa

Hydraulic drive octopus marine

Sail and Rigging

Mast :

Carbon fiber mast , boom, gaff.

Textile Dynex dux Stroud/running backstay with Dyneema lashing on bronze chain plate

All pulley from sweeden rutgerson

Sail

Main 69 sqmeter laminate Dimension

Fore 46.7 sqmeter Laminate Dimension

Stay 29 sqmeter Laminate Dimension

Asymmetric 69 sqmeter

All from Hydes Sail

Rope from robline

Winchs

2 self tailing winch 45 hutton bronze

2 self tailing winch 50 hutton bronze

1 self tailing winch 20 hutton bronze for the reefs

stopper, deck rail, deck pulley

Mooring

Anchoring winch, electric drive 12volt bronze Hutton

110 meter galvanized chain 11.35 mm

100 meter polyester mooring rope

1 anchor 45kg spade type

Spare anchor Delta 35 kg + 8 meter chain

Dinghy

3 meter, epoxy, sailing dinghy rigid hull

outboard 2.5 hp, Yamaha 2 stroke

2 lifting davit with pulley on the transom

Safety equipment

Set of parachute flare

Smoke flare

6 life jacket

Aucun commentaire:

Enregistrer un commentaire